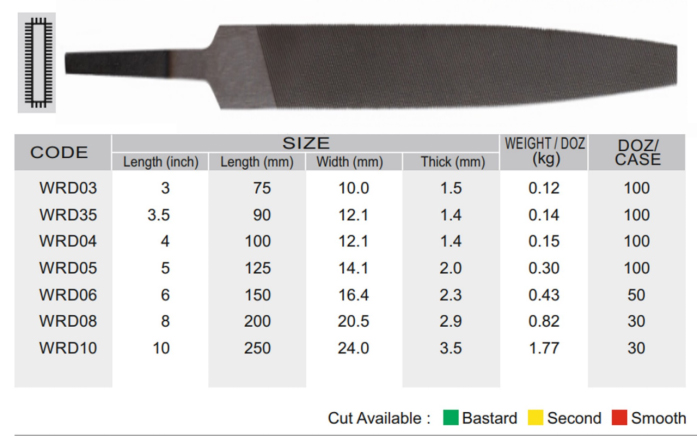

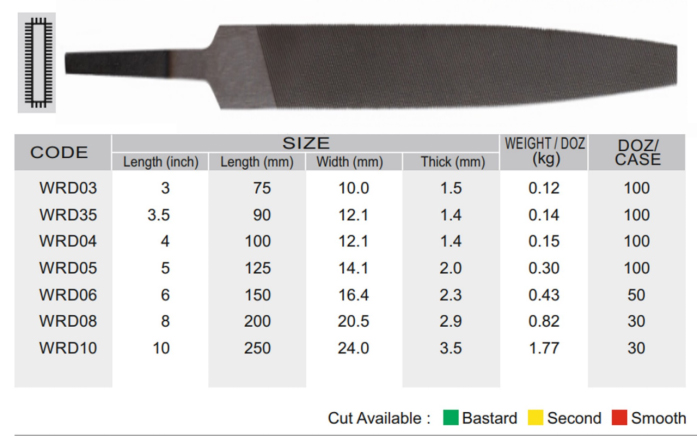

Warding files are used principally by Locksmiths in repairing or filing ward notches in keys. Also suited for use in narrow space. All double cut on sides, singles cut on edges

Mittal Files & Tools Pvt.Ltd. founded & guided under the leadership of Mr. N.K. Mittal in 2010, is today India's 2nd largest manufacturer of Steel files and Agriculture tools, with an annual capacity of over 30 million pieces per annum.

Read More

Mittal Files & Tools Pvt. Ltd. established in 2010, is today India's 2nd largest manufacturer of Steel files and Agriculture tools, with an annual capacity of over 30 million pieces per annum.

Mittal Files & Tools Pvt. Ltd. has three manufacturing facilities in India producing wide range of steel files with over 2 million pieces each month as per International Standards like I.S.S, B.S.S, F.S.S, D.I.N & J.S.S that meet our Customers' requirement by committing to ensure consistent quality, timely delivery & satisfying customary needs of the times.

Mittal Files & Tools Pvt. Ltd. has its Global presence and is strengthening its International footprints through exports to over 33 major countries in North, South and Latin America, Central & South Africa, South Asia, South-East Asia, Europe & Middle East accounting 90% of its total sales .

Pillar Machinist Files, Knife Machinist Files, Warding Machinist Files, Three-Square Machinist Files, Square Machinist Files, Round Machinist Files, Half Round Machinist Files, Hand Machinist Files, Flat machinist files.

"Warding Machinist Files" typically refers to the process of creating precision tools used in machining operations. Machinist files are hand tools used for shaping and smoothing metal or other materials. "Warding" refers to a particular type of file, known for its narrow shape and fine teeth, often used for intricate work.

To create warding machinist files, you would typically start with a blank piece of high-carbon steel, which is then forged into the desired shape. The teeth are then cut or ground into the file's surface at precise intervals and angles to ensure effective material removal without damaging the workpiece.

The process requires precision and attention to detail to ensure that the files perform their intended function accurately. This includes careful control of the file's dimensions, tooth spacing, and sharpness.

Additionally, after the initial manufacturing process, the files may undergo various treatments such as heat treatment to harden the steel and increase durability, as well as surface finishing to ensure smooth operation.

Overall, creating warding machinist files is a skilled process that requires both technical expertise and craftsmanship to produce high-quality tools essential for precision machining work.

Advantages of Warding Machinist Files:

Warding files are designed with a safe edge, which means one edge is smooth and does not cut. This feature allows machinists to file surfaces without accidentally damaging adjacent surfaces or creating unintended scratches, ensuring precise and clean finishes.

The smooth edge prevents the file from digging into adjacent surfaces, reducing the risk of damaging delicate or critical parts during filing operations. This is particularly advantageous when working on intricate or high-value components where any damage could be costly. Despite the safe edge, warding files are still capable of aggressive cutting when needed. Machinists can use the cutting edge for shaping and material removal while relying on the safe edge for precision work, offering versatility in various filing applications.

Warding files can streamline filing tasks by eliminating the need for additional protective measures or careful maneuvering to avoid damaging adjacent surfaces. This efficiency can contribute to faster completion of machining projects and increased productivity in the workshop. The safe edge reduces the likelihood of accidents and injuries caused by accidental slips or misjudgments during filing. Machinists can work with greater confidence knowing that the risk of damaging workpieces or injuring themselves is minimized with warding files.

The smooth safe edge allows for precise blending and finishing of surfaces, resulting in high-quality final products with minimal imperfections. Whether deburring, chamfering, or refining edges, warding files contribute to achieving smooth and professional finishes. With proper care and maintenance, warding files can have a long service life, providing consistent performance over time. This durability makes them a cost-effective investment for machinists and workshops, reducing the need for frequent replacements.

Warding files are commonly available in various sizes and configurations, making them accessible to machinists with different preferences and requirements. Whether for small-scale precision work or larger filing tasks, there is likely a warding file suitable for the job.

Warding files are commonly available in various sizes and configurations, making them accessible to machinists with different preferences and requirements. Whether for small-scale precision work or larger filing tasks, there is likely a warding file suitable for the job.

Warding files are used principally by Locksmiths in repairing or filing ward notches in keys. Also suited for use in narrow space. All double cut on sides, singles cut on edges

The "Warding Machinist Files" application could be utilized in various industries where precision machining is a critical component of production.

1.Automotive Industry Precision machining is essential for manufacturing automotive parts. This application could aid in producing precise components for engines, transmissions, chassis, and other critical parts.

2.Aerospace Industry: Aerospace engineering demands the highest level of precision and reliability. Machined components used in aircraft and spacecraft require extremely accurate measurements, making this application invaluable.

3.Medical Device Manufacturing: Machining plays a crucial role in producing medical devices, implants, and surgical instruments. The Warding Machinist Files application could ensure the precise fabrication of these critical tools, contributing to the safety and effectiveness of medical procedures.

4.Electronics Industry: Precision machining is vital for creating components used in electronic devices, such as computer parts, smartphone components, and semiconductor equipment. This application could assist in manufacturing these intricate parts with high accuracy.

5.Tool and Die Making: Machinists in the tool and die industry produce molds, dies, and cutting tools used in manufacturing processes across various sectors. The Warding Machinist Files application could enhance the precision and efficiency of tool and die manufacturing.

6. Defense and Military: Defense equipment often requires complex and precise machining for components used in weapons, vehicles, and communication systems. This application could aid in producing military-grade components with strict adherence to specifications.

7.Oil and Gas Industry: Machining is essential for producing equipment used in oil drilling, refining, and transportation. This application could ensure the precise fabrication of components used in pumps, valves, and pipelines.

8. Precision Engineering: Industries such as optics, robotics, and instrumentation rely on precision machining for manufacturing components with tight tolerances. The Warding Machinist Files application could support the production of such high-precision parts.